Steam Sterilization of Herbs and Spices

Steam sterilization is a widely used method for ensuring the safety and quality of herbs and spices in the food industry. By subjecting the products to high-temperature steam, this process effectively eliminates microorganisms, pathogens, and pests that may be present. In this report, we will explore the benefits and considerations of steam sterilization for herbs and spices.

The Steam Sterilization Process

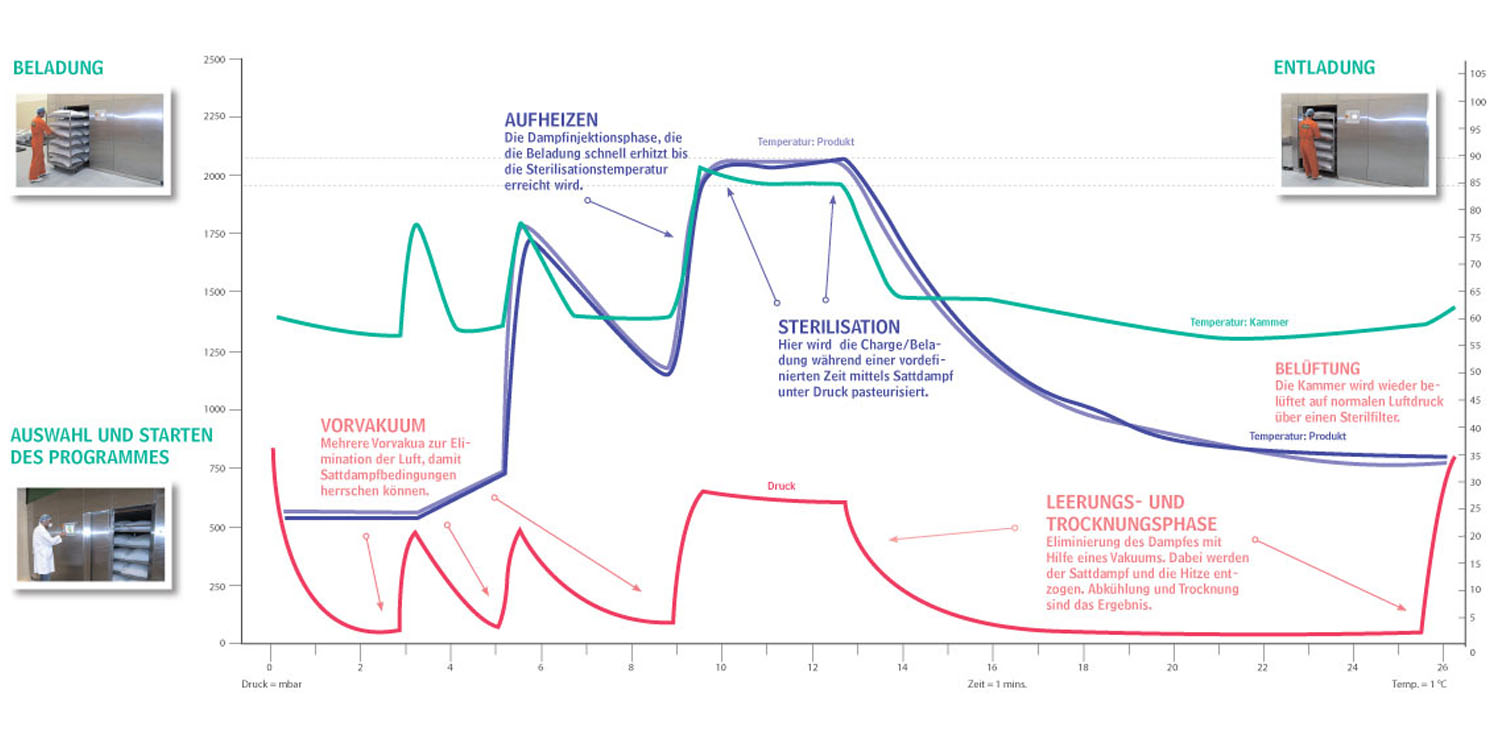

- Preparing the sterilization chamber: The chamber is cleaned and sanitized to create a hygienic environment for the steam sterilization process.

- Loading the herbs and spices: The products are carefully arranged in the sterilization chamber, ensuring proper air circulation and steam penetration.

- Steam injection: Saturated steam is injected into the chamber, raising the temperature and creating a high-humidity environment.

- Sterilization phase: The products are exposed to steam at a predetermined temperature and duration, effectively killing microorganisms and pathogens.

- Cooling phase: After sterilization, the products are cooled down to a safe temperature to prevent moisture condensation and ensure product integrity.

- Unloading: The sterilized herbs and spices are removed from the chamber and prepared for packaging or further processing.

Benefits of Steam Sterilization

- Effective microbial reduction: Steam sterilization is highly effective in eliminating a wide range of microorganisms, including bacteria, molds, yeasts, and fungi. This helps to ensure the safety and quality of the products.

- Preservation of sensory and nutritional qualities: Steam sterilization allows for the preservation of the natural flavors, aromas, and nutritional properties of herbs and spices. The process does not introduce chemicals or alter the inherent characteristics of the products.

- Versatility: Steam sterilization can be applied to a variety of herbs and spices, including both heat-sensitive and heat-resistant varieties. It is a versatile method suitable for different product types and sizes.

- Cost-effective: Steam sterilization is a cost-effective method compared to other sterilization techniques. It requires relatively simple equipment and does not involve the use of chemical agents, reducing operational costs.

Considerations and Challenges

- Temperature and time control: Proper control of sterilization temperature and duration is critical to ensure effective microbial reduction without compromising the quality of the products. Careful monitoring and validation of the process parameters are necessary.

- Moisture content: Herbs and spices may have varying moisture contents, which can affect the steam sterilization process. Optimal moisture levels need to be maintained to achieve desired sterilization results and prevent moisture-related issues such as clumping or texture changes.

- Packaging and storage: Sterilized herbs and spices should be properly packaged and stored to maintain their quality and prevent recontamination. Suitable packaging materials and storage conditions must be chosen to ensure product safety and shelf life.

- Regulatory compliance: Compliance with food safety regulations and industry standards is essential when using steam sterilization for herbs and spices. Manufacturers should stay updated on relevant guidelines and requirements to ensure legal and safe practices.

Summary

Steam sterilization is a reliable and effective method for ensuring the safety and quality of herbs and spices. By utilizing high-temperature steam, this process eliminates microorganisms while preserving the sensory and nutritional qualities of the products. However, proper control of process parameters, moisture content, packaging, and adherence to regulatory requirements are crucial for successful implementation. Steam sterilization provides the food industry with a valuable tool to enhance the safety and extend the shelf life of herbs and spices, ensuring that consumers can enjoy these products with confidence.