ETO Sterilization Enhancing

When it comes to the production of dried herbs and spices, ensuring their safety and extending their shelf life is of utmost importance. Gas sterilization units, particularly those utilizing Ethylene Oxide (ETO) , have become essential tools in the industry. In this article, we will explore how gas sterilization units can effectively enhance the shelf life and safety of dried herbs and spices.

The Power of Gas Sterilization

Gas sterilization units, such as those employing Ethylene Oxide , are designed to eliminate harmful microorganisms, pathogens, and pests from dried herbs and spices. These gases penetrate deep into the plant material, targeting bacteria, molds, yeasts, and fungi without compromising the herbs' quality, aroma, or therapeutic properties.

Ethylene Oxide (ETO) Sterilization Processing

ETO sterilization is a widely recognized method in the industry for its effectiveness in eliminating microorganisms. It is particularly suitable for herbs and spices that are heat-sensitive. ETO gas, combined with other substances like steam, is used to create a controlled environment within the sterilization unit. This low-temperature process ensures the preservation of natural flavors, aromas, and therapeutic compounds while effectively eliminating potential contaminants.

1. PreparationPrior to sterilization, the herbs are carefully cleaned and inspected to remove any visible impurities or contaminants. This step ensures that the herbs are ready for the sterilization process.

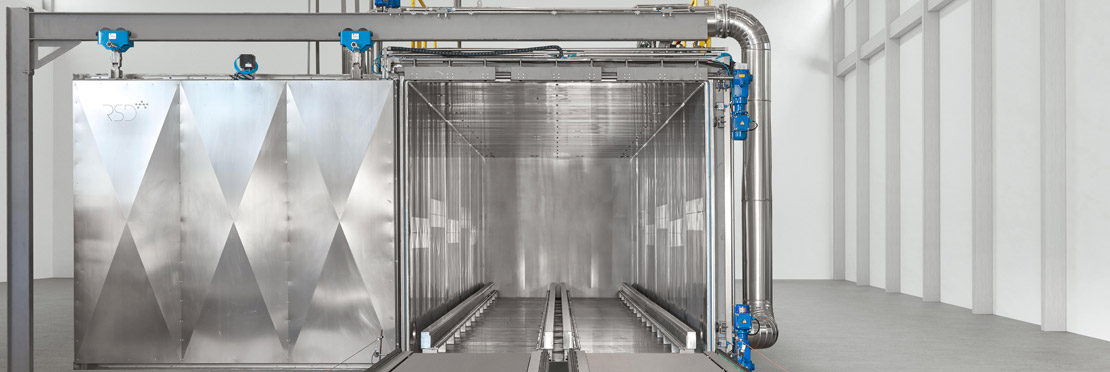

2. LoadingThe prepared herbs are loaded into a sterilization chamber in a manner that allows for adequate airflow and exposure to ethylene oxide gas. Proper spacing and arrangement of the herbs are important to ensure thorough sterilization.

3. Sterilization CycleThe sterilization cycle consists of the following phases: The chamber is sealed, and the temperature and humidity are gradually increased to prepare the herbs for sterilization. Ethylene oxide gas is introduced into the chamber, and the temperature, humidity, and exposure time are carefully controlled to ensure effective sterilization. The gas penetrates the herbs and eliminates microorganisms. After the sterilization phase, the chamber is aerated to remove residual ethylene oxide gas and lower its concentration to safe levels. This step is crucial to ensure the herbs are safe for consumption.

Monitoring and Validation

Throughout the sterilization process, monitoring and validation are performed to ensure that the proper conditions are maintained and that effective sterilization is achieved. This may involve monitoring temperature, humidity, gas concentration, and exposure time.

Extending Shelf Life and Ensuring Safet

Gas sterilization units play a crucial role in extending the shelf life of dried herbs and spices. By eliminating harmful microorganisms, these units help prevent spoilage and degradation, preserving the freshness, potency, and overall quality of the products. The controlled environment and precise monitoring of temperature and humidity within the sterilization unit ensure optimal conditions for both sterilization and long-term preservation.

is a critical step in ensuring the safety, quality, and compliance of the sterilization process. After herbs have undergone a sterilization method such as ethylene oxide (ETO) sterilization, it's important to carefully assess the herbs to confirm that they meet the required standards for consumption or use. Here are some key considerations for post-sterilization inspection of herbs.

-

Residue Testing

One of the primary concerns after ETO sterilization is the presence of residual ETO on the herbs. Testing should be conducted to ensure that any ETO residues are within safe limits established by regulatory authorities.

-

Microbiological Testing

While sterilization is intended to eliminate harmful microorganisms, it's important to conduct microbiological testing after the process to verify the absence of pathogens and other contaminants. This testing helps ensure that the herbs are safe for consumption.

-

Sensory Evaluation

ETO sterilization and other sterilization methods can potentially affect the sensory qualities of herbs, including taste, aroma, and appearance. Conduct sensory evaluations to assess whether the sterilization process has altered the sensory characteristics of the herbs.

-

Quality Assessment

Inspect the herbs for any signs of damage, discoloration, or other quality issues that may have occurred during the sterilization process or packaging. Ensuring the herbs' overall quality is essential for maintaining consumer satisfaction.

-

Packaging Inspection

Check the packaging integrity to ensure that it has effectively protected the herbs during sterilization and subsequent handling. Damaged or compromised packaging could lead to contamination.

-

Regulatory Compliance

Verify that the post-sterilization inspection process aligns with regulatory requirements and guidelines for herbs intended for consumption. Compliance with these standards is crucial for the safety of consumers.

-

Documentation

Keep detailed records of the post-sterilization inspection process, including testing results, evaluations, and any corrective actions taken. Proper documentation demonstrates due diligence and helps in case of audits or inquiries.

-

Validation and Verification

If the sterilization process was modified or if there were changes in equipment, validate and verify that the modifications do not adversely affect the herbs' safety and quality.

-

Expertise

Post-sterilization inspection requires expertise in microbiology, quality control, food safety, and regulatory compliance. Engage professionals who are knowledgeable in these areas to conduct thorough inspections.

-

Continuous Improvement

Use the findings from post-sterilization inspection to identify areas for improvement in the sterilization process, packaging, or handling procedures. Continuous improvement helps enhance the overall quality and safety of the herbs.

Remember that post-sterilization inspection is a crucial part of the quality assurance process and should be conducted diligently to ensure that sterilized herbs meet the required standards for safety and quality before they reach consumers.